Winter hive insulation is one of those things that you either believe in, or you don’t. And there is no arguing with the fact that the majority of managed bees live in uninsulated wood boxes, even in the frigid north.

However, that doesn’t mean that there aren’t benefits to insulation installed around the hive sides, or in using polystyrene hives like BeeMax or Lyson.

In the middle of the 1800s, the Langstroth hive design revolutionized beekeeping by introducing moveable frames in stackable boxes. At the same time, it moved managed bees out of traditional enclosures like straw skeps and bee gums. The new design presented a challenge to bees as it further increased the difference between their natural, thick-walled tree cavities and man-made hives.

Bees being bees, they managed to adapt to the much-skimpier walls of their new enclosures, even in cold climates.

And beekeepers being beekeepers, once they realized their bees wouldn’t freeze to death in the new, thinner-walled boxes, adopted them wholeheartedly.

But even Reverend Langstroth himself didn’t advocate for wintering in single-walled boxes. He constantly urged beekeepers in cold climates to use double-walled boxes filled with charcoal, straw, or other insulating materials. He recognized that one layer of pine lumber didn’t come close to the insulative value of tree cavities or straw skeps.

Of course, unlike today, at the time of his invention, 1” thick pine boards were actually 1” thick. White pine has an R-value of about 1.4 per inch of thickness. R-value is a standard measure of how much a material slows the loss of heat through it. That makes the R-value of the walls of an industry-standard, ¾ inch-thick pine bee box about R-1.

In contrast, a tree cavity will have much thicker walls. The R-value of the “walls” surrounding honey bee tree cavities may range from R-5 to even higher.

Why does the R-value of bee box walls matter?

It is an axiom of winter beekeeping that “bees don’t heat the hive, they heat the cluster.” And that’s true. But it also overlooks physics. The cluster, being the warmest object within the box, constantly loses some of its heat to the surrounding air due to radiation and convection. That warmed air will, in turn, pass its warmth to whatever it contacts, which is the inside surface of the hive body. At that point, the heat passes through the wood and is lost to the outside. The R-value is a measurement of how efficiently that will happen. A low R-value means the warmth will be transmitted easily; a higher R-value means it will be lost much more slowly.

Although the bees’ winter clustering behavior means they can keep themselves warm enough to survive even when the outside temperatures fall below zero, it is not without costs. Honey is the principal fuel for this amazing feat, but there is also likely a cost to the bees’ bodies as their muscles and tissues must convert the honey into heat in order to live. A thicker, or higher R-value, wall around the cluster’s space reduces the amount of energy and the physical effort needed. It’s as simple as that.

And it has one other practical consequence: the cluster must maintain its dense coherence or it will fail to keep the bees warm enough. This means that during extended periods of cold, the cluster must stay fixed in one place, perhaps staying long enough to run out of accessible honey. More retained warmth, retained longer, even if it’s just a modest increase, may allow the cluster to loosen and move enough to reach additional frames of honey.

Although he didn’t know about the modern standard, Langstroth, when he urged beekeepers to use double-walled boxes, was attempting to increase the R-value. Making boxes out of wood as thick as a tree-trunk has always been impractical due to the weight. Double walls with an open space between, can be filled with a lighter material, saving weight and increasing the heat retention within the hive.

Modern building materials offer an even better solution: expanded polystyrene foam. XPS, as it is often called, is extremely lightweight and at the same time it has an intrinsic R-value that is about three times that of pine. The R-value of 1 inch of XPS is R-5. If Langstroth were alive today, XPS might be his preferred material for his new hive design. That extra R-value is one of the principal benefits of BeeMax and Lyson hive equipment. The R-value of the materials used in their walls is more than R-6.

But what if you already have, or even prefer to use, wood bee boxes? Your bees are not condemned to suffer through chilly winters. You can add insulation around the hive, significantly increasing the R-value of the walls when it is most needed.

How to insulate your hives

There are three ways to do this: you can use hive wraps such as the Bee Cozy, or the Ez-On hive wrap. Or you can use homemade panels of XPS foam board.

The advantage of the Ez-On hive wrap is that it is by far the easiest to install, since it is simply wrapped around the hive and then kept snugged against it using a full-length Velcro™ closure. There are 8-frame, 10-frame, and nuc box-sized wraps available. They can be installed at any point, without disturbing the hive at all. The material in this type of hive wrap has an R-value of R-4. With a height of 17”, it fits a double deep hive perfectly.

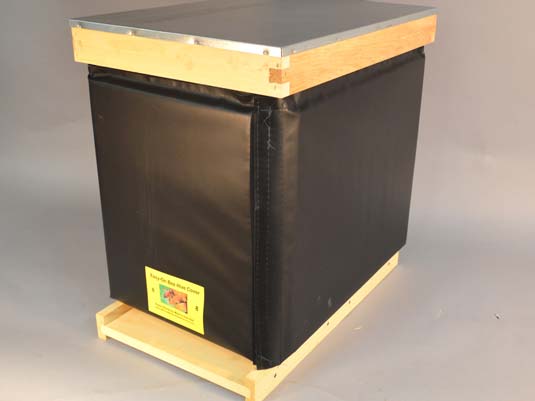

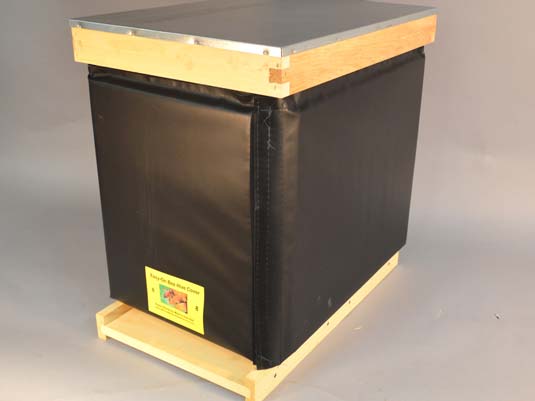

A Bee Cozy is a fiberglass-filled, plastic-covered sleeve that is slipped down over the hive, while the cover has been temporarily removed for installation. It is kept snugly in place with a few strategic staples. The fiberglass insulation inside the Bee Cozy offers double the R-value (R-8) when compared to the material in the Ez-On hive wrap. Because it is softer, it is a bit more forgiving if your hive stack is somewhat untidy, with the boxes not stacked up perfectly. It is also taller, so it will cover two deeps, two deeps plus a super, or a four-medium stack. It is available for both 8-frame and 10-frame equipment.

Bee Cozy hive wrap

Ez-On hive wrap

You can also make your own insulation panels from XPS sheets. This would give you complete flexibility if you run a non-standard hive configuration or want additional R-value. The panels are held firmly against the hive exteriors using electrical tape, 3M Original Blue™ painters’ tape, a bungee cord or rope. It’s best to paint the XPS on both sides to prevent warping and protect it from UV degradation.

In all cases, it’s important to keep the hive wrapping as close to the exterior surface of the boxes as possible. Do not leave any extra space between the insulation and the box because bees will find their way behind the wraps, become chilled and die. Now, while it is still warm enough to do it easily, it’s smart to put extra attention to getting your boxes stacked up perfectly square. This makes it so that the insulation has no gaps behind it to lure bees to their deaths on warm winter days.

Is it worth the extra effort and cost to insulate, or not?

Well, as I wrote at the top of this article, there are firmly-held positions on both sides. Personally, I am an advocate of insulation; all of my own hives have at least 2” of XPS insulation all around them. I have always had excellent wintering results. On the job however, I have the care of a couple of dozen hives in the teaching apiary. Almost all of them are uninsulated. And except for hives lost to mites, I see good wintering results there, too.

I believe hive insulation makes life less stressful for bees during the winter. It certainly does no harm. So, my recommendation is: insulate your hives if you live in a cold area, say USDA Zone-5, or lower. You will be less worried about your bees when the weatherman forecasts extremely cold weather.

No matter where you live, or if you’re on the fence about winter insulation, at least add a 1”-thick piece of insulating foam board to your cover assembly. Or consider using an insulated telescoping cover. Since heat always rises, both human houses and bee hives lose the most warmth through their attics. The XPS foam board is tucked up under the telescoping cover, above the inner cover. In addition to conserving warmth, it also helps reduce the amount of condensation that can fall down on the bees if you’re not using a quilt box. It’s a good idea to add a hive strap or a weight on your cover as the overhang of the telescoping cover will be reduced by the thickness of the insulation. It’s fine to leave the cover insulation on the hive year-round as it will also help keep your hive cooler when the sun is beating down.

A very unconventional hive wrap made up of a thick layer of wool blankets, covered with a tarp held in place with clothespins and ratchet straps. The political signs in front are just leaned against the hives, leaving plenty of space behind them open for ventilation. This shows that there are many ways to insulate hives. This was my first winter – as I got more hives, I ran out of blankets and switched to homemade XPS panels. They are a lot less work! -ntw